Why Embodied Carbon Is Reshaping Commercial Real Estate

August 8, 2025

Understanding the Financial, Regulatory, and Strategic Impacts Beyond Sustainability

The Carbon Blind Spot in Real Estate

Commercial real estate has long prioritized energy efficiency, but most conversations have focused on operational carbon—emissions from lighting, heating, and cooling buildings over time. What’s often overlooked is embodied carbon: the greenhouse gas emissions generated during the production, transportation, and installation of building materials. Unlike operational emissions, which unfold over decades, embodied carbon is emitted upfront—often before a building is even occupied.

As operational systems become cleaner through improved codes and technology, embodied carbon is becoming a larger share of the industry’s total emissions. By 2050, projections show that embodied carbon will account for up to 50% of the total carbon footprint in new construction. With new policies, investor expectations, and material performance benchmarks emerging, it’s now a critical factor for developers, design teams, and financial institutions alike. Understanding where these emissions come from and how to manage them is no longer optional—it’s a growing part of project value, risk, and compliance.

How Is Embodied Carbon Measured?

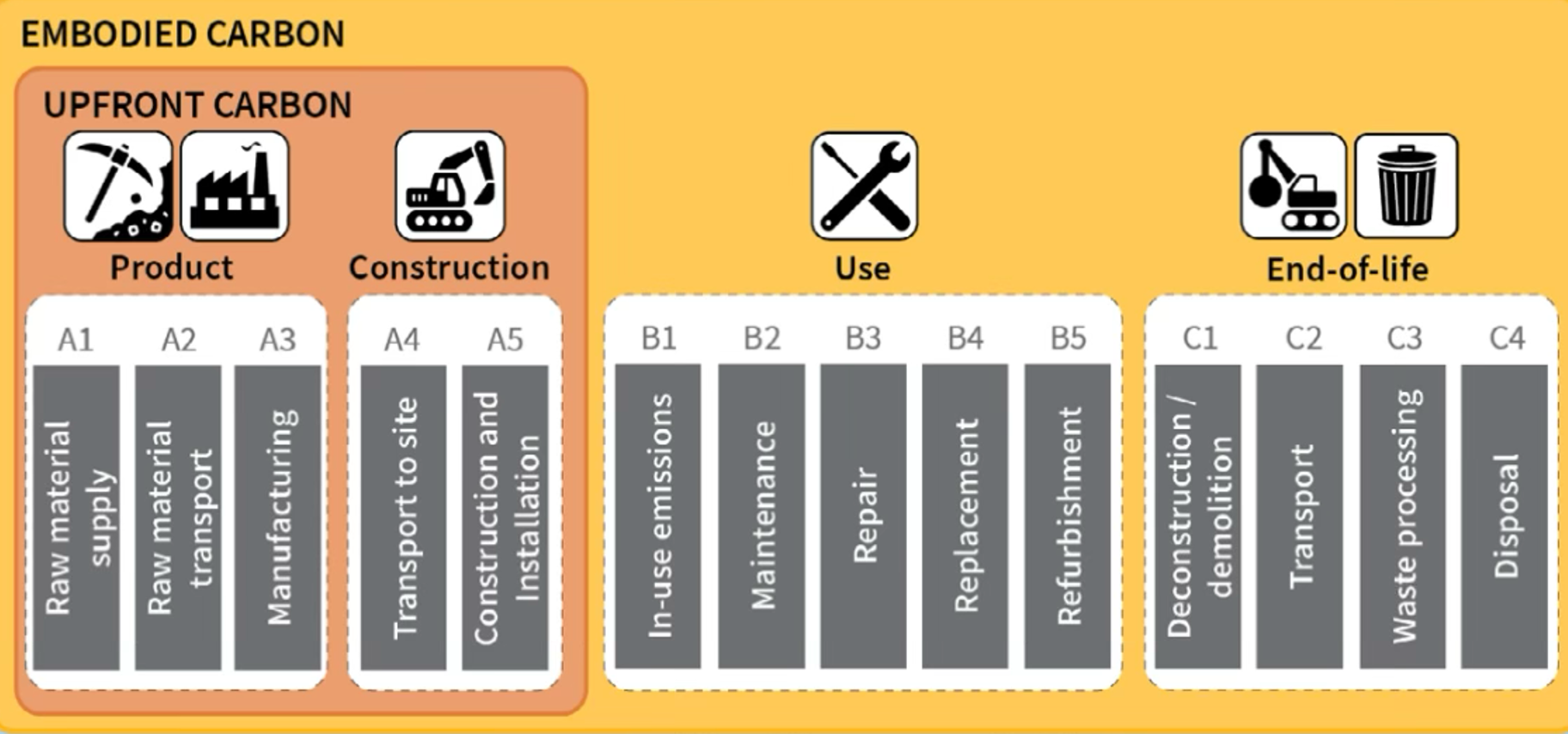

Embodied carbon is most commonly measured through a Life Cycle Assessment (LCA), a method that evaluates the environmental impact of building materials over their entire life cycle. The most common metrics used in LCAs include Global Warming Potential (GWP - expressed in kg CO₂e), Environmental Product Declarations (EPDs – industry gathered reports providing carbon data on specific materials), and associative data within Life Cycle Stages (such as A1–A3: raw material supply, transport, and manufacturing, A4–A5: transport to site and construction, and B–C: use, maintenance, and end-of-life).

EMBODIED CARBON LIFECYCLE STAGES

* Image Resource: Carbon Leadership Forum (CLF): CLF Embodied Carbon Policy Toolkit, Building LCA 101

These assessments allow AEC consultants like our team at Marx Okubo to analyze the comparison between different material systems—e.g., concrete vs. steel vs. timber—and choose lower-carbon alternatives without compromising design intent or durability.

Where Embodied Carbon Lives in Buildings

The majority of a building’s embodied carbon is concentrated in a few key areas: structure, enclosure, and primary interior assemblies. Substructure and superstructure systems, exterior walls and roofing, and interior framing and drywall partitions consistently carry the highest carbon load. These elements also represent the foundation of most industry benchmarking efforts and regulatory reporting.

Because these systems are established early in design and involve large material volumes, they offer the greatest opportunity for meaningful carbon reductions. Careful evaluation at this stage can reveal lower-carbon alternatives and more efficient assemblies—often with cost benefits tied to material use, labor, and sequencing.

Why This Matters to the Commercial Real Estate Industry (Not Just the Environment)

For many professionals, the topic of embodied carbon still feels like a niche sustainability concern. But it’s becoming a strategic issue for four major reasons:

1. Regulatory Momentum Is Accelerating

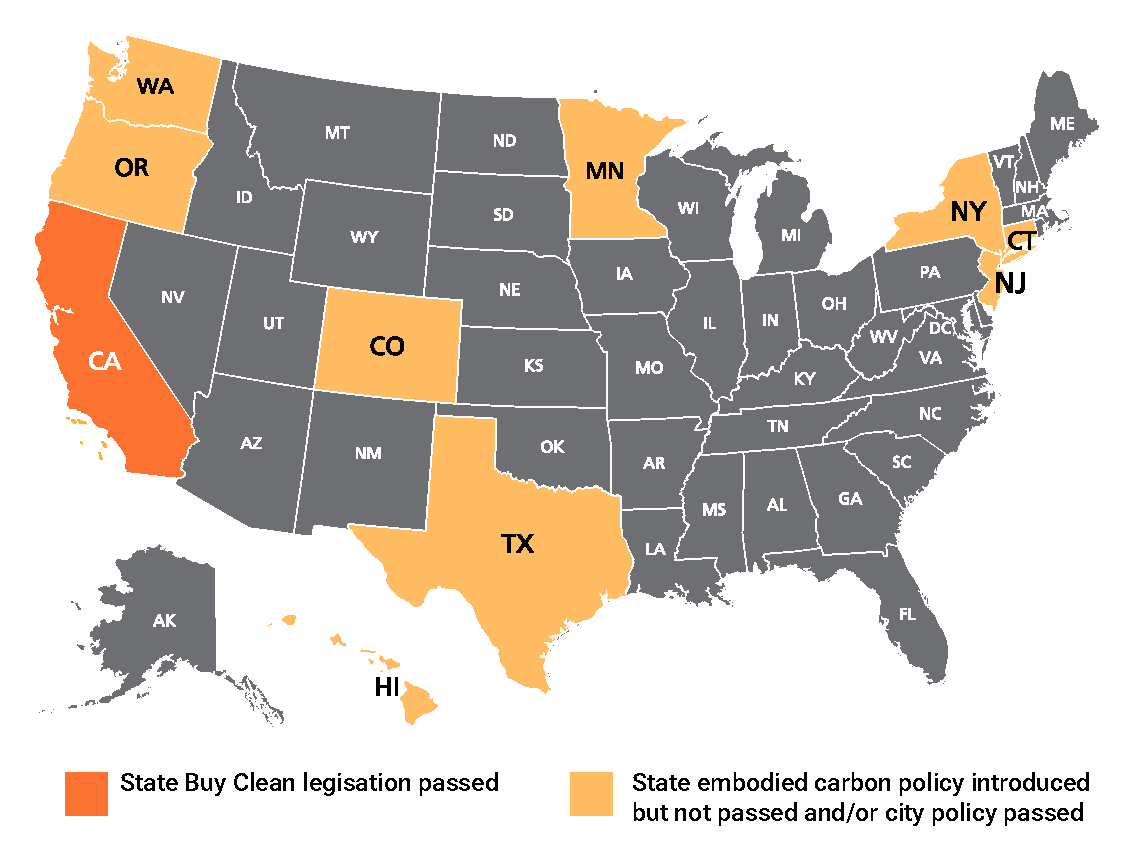

We have discussed previously that states like California, Colorado, Washington, and New York have had growing regulatory changes over the years. Some of these states are adopting embodied carbon policies that tie into building codes, procurement standards, and environmental reviews. California’s CALGreen Code now mandates whole building LCAs or material-specific limits on large non-residential projects. Seattle, Denver, and Portland are following suit. These policies are quickly becoming compliance obligations, not optional green practices. The map below represents the states that have mandated or introduced embodied carbon specific polices, as of Q1 2025.

STATE BY CLEAN EMBODIED CARBON POLICY MAP

*Reference: Carbon Leadership Forum (CLF): CLF Embodied Carbon Policy Tracking Map – Q1 2025

2. Avoided Costs = Competitive Advantage

Embodied carbon analysis is not just a sustainability measure—it’s a design and investment strategy. When performed during early design, it allows an opportunity to assess whether material selections will comply with emerging carbon regulations, identify low-carbon alternatives that may also reduce construction costs, and ensure alignment with investor or portfolio-wide climate goals. On both a national level and in the European Union market Corporate Sustainability Reporting Directive (CSRD), these insights can prevent costly redesigns, simplify permitting, and shape procurement strategies long before materials are purchased or installed.

At Marx Okubo, we’ve supported equity investors through precisely these scenarios. In California, we partnered with the primary investor on an 8-story, 270,000-square-foot, 225-unit, mixed-use, multifamily residential development during design development to evaluate the embodied carbon profile of a proposed concrete structure. Our analysis demonstrated that switching to a cross-laminated timber system would not only lower the project’s global warming potential (achieved a 47% reduction in GWP), but also generate savings in materials, labor, and construction schedule. In Florida, we conducted a post-construction LCA (Stages A1–A5), to a 3-building, 310-unit multifamily development for an investor with European climate reporting requirements. The analysis provided real-time data on the project’s embodied carbon footprint and informed the client’s strategy for reducing GWP and cost on their next U.S. project.

3. Sustainability Expectations Are Reshaping Investor Priorities

Embodied carbon is becoming part of the conversation when evaluating long-term asset performance and making funding decisions. Investors increasingly want to understand the environmental impact of a building’s materials and construction, how it aligns with regulatory compliance and portfolio goals, and how these factors relate to overall project cost.

When carbon analysis is integrated early in the process, design and material decisions can be aligned with both sustainability goals and investor requirements. At Marx Okubo, we have helped bridge that gap by turning technical carbon data into clear, actionable strategies—supporting design teams and owners in choosing materials and systems that meet performance targets, reduce risk, and support a more cost-effective, compliant outcome.

4. Design Optimization and Procurement Strategy

Taking a holistic approach to embodied carbon early in design can do more than reduce emissions. It can help teams make strategic decisions that avoid costly compliance challenges in other areas—such as energy code upgrades, envelope performance, structural overdesign, or mechanical system oversizing. By evaluating material systems through carbon, cost, and code lenses together, project teams are better positioned to streamline construction, reduce documentation burdens, and adapt more smoothly to tightening building codes and evolving sustainability mandates.

In our experience, we’ve seen effective results when we have supported clients in evaluating material systems and assemblies during schematic design, using comparative analysis to guide informed decisions. In some cases, this has involved reviewing EPDs, providing clarity on material impacts, and aligning selections with regional regulations. These early steps not only support carbon reduction goals but also help teams avoid costly changes later in the process.

Practical Reduction Strategies That Deliver

Teams working in commercial real estate can make significant embodied carbon reductions using four core strategies:

- Build less, reuse more - Reusing buildings or building components can cut emissions dramatically. Some jurisdictions offer incentives or credit pathways for reuse.

- Build lighter and smarter - Reducing material volume without sacrificing performance—e.g., post-tensioned slabs or composite systems—offers both carbon and cost savings.

- Substitute high-impact materials - Using alternate material choices such as low-carbon concrete mixes, sustainably harvested timber, or recycled steel can immediately reduce embedded carbon emissions relative to their baseline choices.

- Procure verified low-carbon products - Leverage tools like the EC3 (Embodied Carbon in Construction Calculator) tool or Tally (building life cycle assessment plug-in for Revit) to compare GWP data and material EPDs and identify product-level carbon savings.

Embodied carbon is now part of the equation. Whether a project is just taking shape, ready to break ground, or already built. For investors, developers, and architects, understanding when and how carbon impacts project goals has become essential. At Marx Okubo, we assess embodied carbon risks and opportunities at every stage: reviewing early-phase concepts to ensure alignment, verifying compliance and performance during construction, and evaluating outcomes against carbon targets and investor expectations. This holistic perspective allows us to serve as a strategic voice, by translating data into insights that protect value, support alignment, and uncover missed opportunities.

Stay tuned for Part 2, where we’ll explore how regulations are changing across the country and what embodied carbon means for compliance, reporting, and the future of development. If your team is already asking how to stay ahead of these shifts, we’re here to support that conversation.

Contributors: Dustin Casper, Robert Phinney, Noelani Maylad, Annie Chang, and Erin Walrath

Marx Okubo is a national architecture/engineering/construction consulting firm that works with real estate owners, investors and lenders—at every point of the property lifecycle—to evaluate their building projects, solve complex challenges and implement tailored solutions. We help clients understand their projects’ complexities, so they can make more informed decisions and, ultimately, mitigate their risk.